Table of Contents

Definition

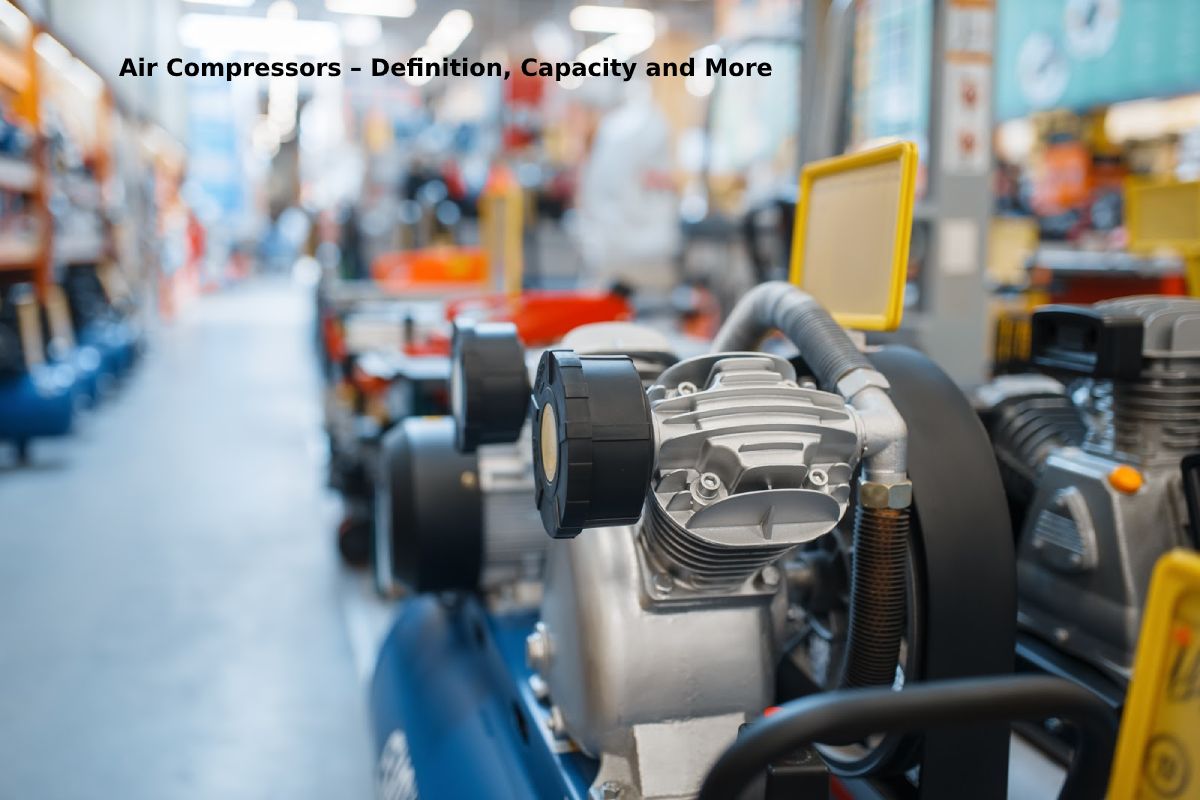

Air Compressors is a mechanical device containing pistons and valves, which collects air and compresses it into a tank to a certain extent. And the air pressure mechanism is formed by reducing its size.

Vehicle air compressors are combustion engine compressors. Relying on the regular movement of the piston up and down through which the air enters and is compressed into the tank. And some types rely on membranes to pull the air and compress it. And prevent it from going backward and out of the tank during the collection process.

The compressor industry has evolved in our time and today the compressor is able to store gas at tremendous pressure to be ready for industrial uses.

The principle of its work is similar to the creation of pumps in that both can increase fluid pressure and transport it through pipes, but in compressors, gases press and decrease their size, but in pumps, the fluids are non-compression materials that maintain their size. And the pressure results in a force that transports the liquid from one place to another. And this is the principle of the work of fluid pumps.

Air Compressor Capacity

The air compressor capacity determines by determining the amount of air that can enter the tank to compress it to a certain extent. Usually, pressure is 690 kph at 20°c and humidity 38%, and the compressor capacity is measured by a unit of m3/hour.

The name of the compressor is usually included in its capacity. The number of devices that operate using the compressor depends on the size of the gas needed by each device. You cannot utilize too many devices together that need a gas volume more significant than the compressor capacity. If you turn on many beyond the compressor’s capacity, this is causing damage screen.

Types of Air Compressors

Compressors are mainly divided into two types, and each item has several types within it as follows:

Dynamic Compressor Motor

Compressor central compressors: consists of a rotary disc that enters the air parallel to the rotation axis and exits it vertically, and through rotation. The device increases the speed of the gas and increases the pressure. And then converts the gas pressure force into dynamic energy in which the gas rushes. And also, is used when needed for continuous power such as oil purification processes in petrochemical plants. It can double the pressure from such pressures to more than 69,000 pascals.

Axial compressors: in this type of compressor. There is a fan orbiting the axis. The purpose of its presence is to increase the speed of the gas entering the pump and keep it away from the center to reach the dispersed. These compressors are expensive because they contain many pieces and spaces between them calculated with high accuracy and made of high-quality materials.

Positive Displacement Compressors

Reciprocating Compressor: This type of compressor contains piston any piston, this type of single-cylinder or multi-cylinder compressor may be in a more complex sense. Working on one or several stages. The power-driven by either an electric engine or an internal combustion engine.

This type of compressor works with the principle of piston movement. So, the piston moves up works to push the air in and its activity in the other direction works on air pressure to a certain degree. Which leads to opening the propulsion valve. And also, exiting the air powerfully.

Rotary compressor: A compressor that contains a decentralized rotation axis with moving blades, which compresses the gas inside due to its movement, types of which. Scroll compressors, Rotary screw compressors.

Scientific Applications on Compressors

Therefore, Uses multiple compressors. Including what is familiar to us, such as compressors in car maintenance workshops used to fill tires. We use Compressors in air jets to clean cars. The compressor is used to spray paint on buildings.

In factories, compressors are wider: compressors in thermal power plants. And also we use compressed air to push the feather into manual hammers for drilling. We use compressed air to lift cranes. We use it to spray paint on products such as the schiller industries and locations.

Cleaning of machinery and flooring using compressed air. So, we use compressed air in refrigeration processes for industrial processes. We can use Compressed air to control robots in assembly processes.