Table of Contents

Introducing the Pump

The pump is an energy-consuming device for lifting, transporting, or compressing fluids. And the older pumps were water pump boosters, such as Persian and Roman mills and the more complex Archimedes cooler.

Medieval mining led to the development of the suction pump (piston), which Georgius Agricola described in 1556. A suction pump works with atmospheric pressure where the piston remains lifted.

It creates a partial vacuum. External pressure forces water into the cylinder to exit the exit valve.

Atmospheric pressure alone can cause the water to a maximum height of about 34 feet (10 meters), so the power pump was developed to drain water at more extended depths. In the force pump. The piston presses through its downward run water through a side valve to a height that depends simply on the force applied to the piston.

Work Principle

All pumps use the principle of working on natural forces to push liquids (such as water and oils). When the moving parts inside the pump begin to rotate. The air remains expelled out to cause a partial vacuum with slight pressure. Which calls for the liquid to replace it. Which is the principle is very similar to what happens inside the juice-sucking straw when the mouth is emptied of air to fill that vacuum.

Types of Pumps

Pumps are classified into different types, and the most prominent types include: offset pumps, liquid, and gaseous materials being transported from one place to another. Relying on so-called clouds and expulsion through a mechanical change process that occurs specifically for the size of the cylinder. And this type of pump includes other kinds. The most important of which are.

Rotational pumps liquid and sticky materials remain pumped using an electric motor or steam turbine. Which is spiral or helicopter-shaped. And remains named after the cylindrical pistons. Which move the rotational motion, and we use it in forced lubrication and fuel transport.

Frequency pumps medium-viscous liquids are pumped using an electric motor or steam engine. Which is piston-shaped and is named after the cylindrical pistons because the cylindrical pistons move a frequency movement. In addition, we operate in forced lubrication and feeding and fire pumps. And starting and ballast pumps.

Centrifuge pumps here, liquids are pumped using a central ejection force resulting from the rotation of what is known as the feathers through which the fluid passes and includes several types. Most notably axial pumps and country pumps. As well as freshwater pumps, seawater pumps. And boiler feeding pumps.

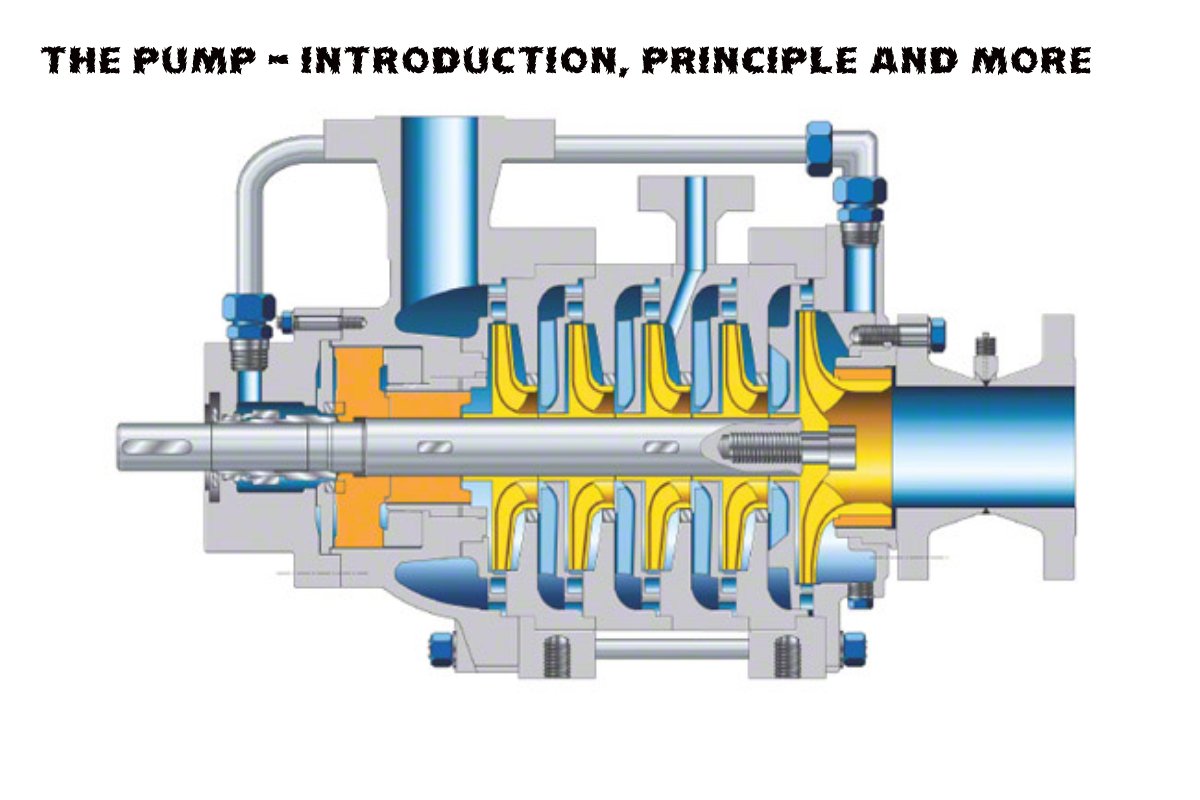

Pump Components

The pump consists of the following parts: impeller is a wheel supported by a series of curved fins. And is installed on the column associated with an external power source that lends liquid energy to the impeller and makes it rotate. And classifies the irons into two types (closed and semi-open cunning).

Outer cover a connected tube at the top end of the pump entrance to the center of the impeller known as the eye.

The dual reaction pump consists of two eye-connected suction tubes on both sides. And the lower end drops to the liquid in the lift. And also, the lower end is installed in the foot valve and drain.

The conduction tube is a line connected at the lower end of its exit and delivers the liquid to the desired height. Near the pump exit in the delivery tube. So, a valve remains provided that controls the flow from the pump to the delivery tube.

Factors Affecting Pump

The selection there is a range of factors adopted in choosing the right pump. Including the pump’s capacity and height remain required. Which controls the speed and dimensions of the feather and the quality of the drug used. Either single or equipped.

The temperature necessary during liquid material infusion varies from pump to pump. Depending on its type and use. Viscosity remains possessed by the material to it.

The type of medium used in terms of its ability to form rust remains determined by the metal used in the manufacture of it.

Therefore, technical considerations when using pumps there is a set of guidelines to consider when using pumps. Including using high lifting pumps in the lubrication cycle. Fuel transport, freshwater, or navel only. Use large pumps in the cooling process or ships. And also use medium-sized pumps to pump fresh water and healthy water.